CNC, or Pc Numerical Handle, encompasses the manufacturing course of action the place machines Slice, carve and kind pieces based on Computer system codes that Manage the cutting tool’s speed and movement.

On the subject of machining centers, there are various kinds of machine centers that cater to distinct manufacturing needs. Just one typical type may be the Vertical Machining Center (VMC), which has a vertical spindle axis. This design and style permits easy accessibility and loading of workpieces from over.

Numerical controls describe how briskly to maneuver the spindle (the rotating portion which spins the Software holder), which route to move, which Software to work with (When the machine takes advantage of various tools and may swap amongst them), and other components like applying coolant.

This system ensures a clean and economical Doing the job ecosystem, contributing into the machine’s longevity and overall performance.

These centers usually include ATC and APC systems but with a far more compact style, earning them well suited for scaled-down Areas or person users.

Step four: Just after this, the operator trials the G-code or other program to look for any apparent problems, before jogging the machining Procedure.

Machining processes produce chips and have to have cooling to take care of Resource lifestyle and element top quality. The chip and coolant managing system manages these factors, collecting chips as a result of chip conveyors and providing the mandatory coolant for the cutting region.

Working with shorter cutting tools with intensive speed ranges, UMCs minimize vibration and more info Strengthen production effectiveness, all whilst reducing cycle situations.

Open up loop systems are less expensive, and as a consequence a lot more frequent on Do-it-yourself CNC routers, but closed loop systems tend to be more advanced and will appropriate mistakes, including in situation of the machine.

Unexciting: Dull is utilized to enlarge current holes with high precision. Unlike drilling, which creates a gap, monotonous wonderful-tunes the diameter to specific tolerances. Unexciting can also be accustomed to correct any misalignment in the outlet, making sure that it is correctly cylindrical.

A 5-axis UMC, one example is, moves the cutting Device along X, Y, and Z linear axes though rotating to the A and B axes. This leads to exceptional precision when crafting factors like aerospace components or advanced molds.

Tapping: Tapping will involve cutting threads inside of a gap, providing a route for screws or other threaded objects.

B5ADV Plus Y500 ROBODRIL is designed to conduct a wider selection of duties and Strengthen productiveness for just about any machining application. The prolonged Y-axis stroke by one hundred mm as well as bigger desk dimensions unlocks a chance to machine big workpieces without having considerably raising the VMC’s footprint.

By knowing how these factors perform jointly, producers can optimize their production processes and realize higher levels of productiveness. It is vital to think about Every part's abilities and routine maintenance requirements To maximise the effectiveness with the machining center.

Angus T. Jones Then & Now!

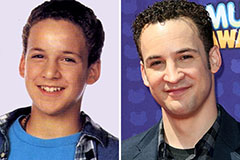

Angus T. Jones Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Danny Pintauro Then & Now!

Danny Pintauro Then & Now! Elisabeth Shue Then & Now!

Elisabeth Shue Then & Now! Kane Then & Now!

Kane Then & Now!